MD-MES System

Production and Manufacturing System

Comprehensive Integrated Solution to Make Intelligent Manufacturing Easier

Product Introduction

MD-MES Production Informatization Management System

Molding MES System is based on the injection molding business-oriented thinking, managing the entire life cycle of the enterprise’s entire business process. It aims to reasonably arrange production scheduling, optimize process flow, improve product quality, strengthen workshop logistics management, reduce energy consumption, decrease inventory, and lower costs. Meanwhile, it seamlessly connects with upstream and downstream systems such as ERP, PLM, WMS, and Industrial Internet of Things, eliminating information silos and effectively improving the efficiency of production and manufacturing operations and informatization management.

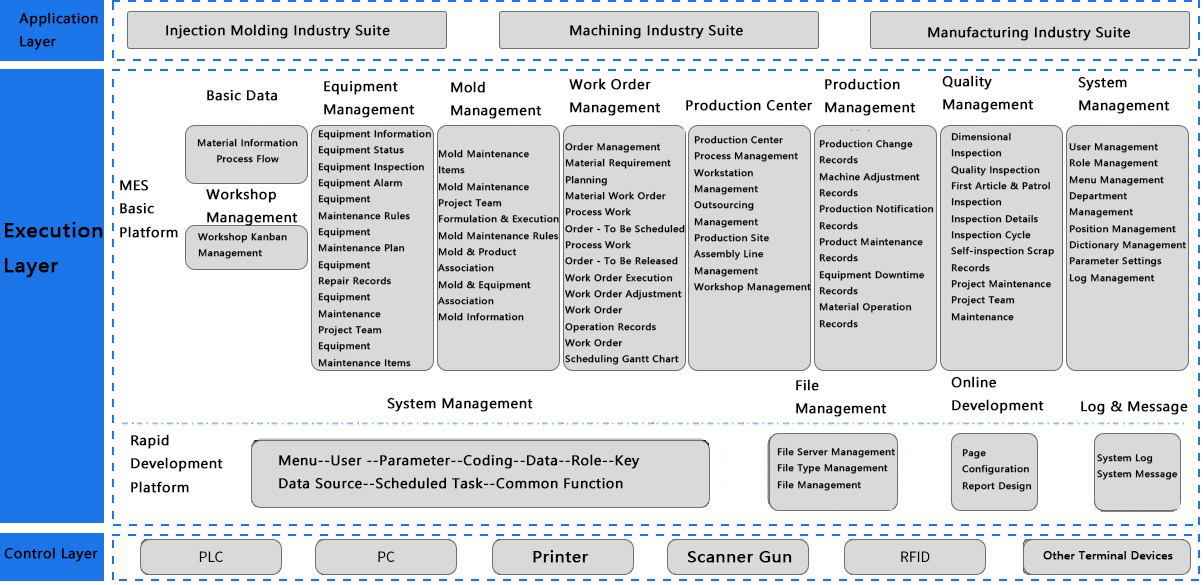

Core Function Modules

Production Planning and Scheduling

1.Receive ERP production plans and decompose them into workshop tasks 2.Conduct intelligent scheduling based on constraints such as equipment capacity and material supply 3.Support dynamic adjustment of production sequence and priority

Production Process Monitoring

1.Real-time collection of equipment status, production progress and quality data 2.Visual display of production workshop operation status 3.Automatic alarm and push for abnormal situations

Quality Management

1.Quality data collection and analysis throughout the production process 2.Digital management of quality inspection standards 3.Defective product traceability and processing process tracking

Equipment Management

1.Monitoring of equipment operation status 2.Formulation and execution of equipment maintenance plans 3.Equipment failure recording and cause analysis

Material Management

1.Production material requirement planning 2.Material distribution tracking 3.Real-time update of inventory status

System Features

real-time

Achieve second-level collection and response of production data

Visualization

Provide intuitive production dashboards and reports

traceability

Completely record the data of the entire production process

Flexibility

Support multiple modes such as discrete manufacturing and process manufacturing

System Module Diagram

Application Value

Increase equipment utilization rate

Reduce work-in-progress inventory

Improve product quality consistency

Shorten production cycle

Achieve transparent management of the production process

Service Commitment

Pre-sales Service Process

1.Demand research and proposal development. Conduct research to understand the company’s current status and future development strategy, clarify functional planning requirements for the factory, and develop targeted factory layout planning solutions.

2.Business negotiation and contract signing. Budget quotation + business negotiation confirmation; contract terms drafting + contract communication and signing.

3.Planning and project monitoring. Submit implementation results in stages: new plant planning functional division, large logistics flow design, production mode optimization, capacity design, warehouse configuration planning, etc. Conduct confirmation of planning results.

4.Implementation guidance and continuous follow-up. Provide guidance for the implementation of planning solutions and follow-up services.

01-Project Initiation

Project Scope

Project Organizational Structure

Project Technology

02-Requirements phase

Define user requirements

URS/RTM/RAM

Project plan

Validation plan

Deliverables list

03-Design phase

PS

DS(IDS/HDS/FDS)

Test plan and procedure

DQ

04-Implementation phase

Development environment

Test environment

Production environment

Implementation records

Issue tracking

Change and deviation handling

Internal testing

C&Q

05-Acceptance Phase

Operating Environment

System Import

User Training

Test Records

FAT(IQ)

SAT(OQ)

06-System Go-Live

Sign Off

System Handover

Document Delivery

Maintenance and Technical Support

Project Quality Assurance

Project Quality Control

Project Team Consultant Expertise Guarantee

After-sales Service Guarantee

Turnkey Project

24/7 After-sales Service

Additional Services