Logistics industry solutions

Choose Maoding, choose safety, choose professionalism

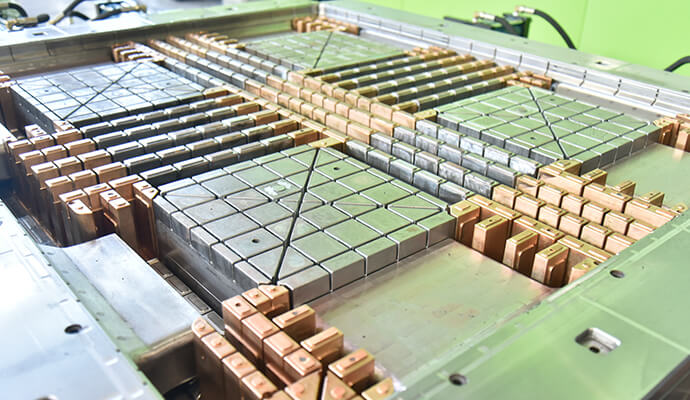

Plastic pallet mold

According to their shapes, plastic pallets can be classified into three types: double-sided plastic pallets, single-sided plastic pallets and light-duty plastic pallets. All three types of pallets have stacking requirements.

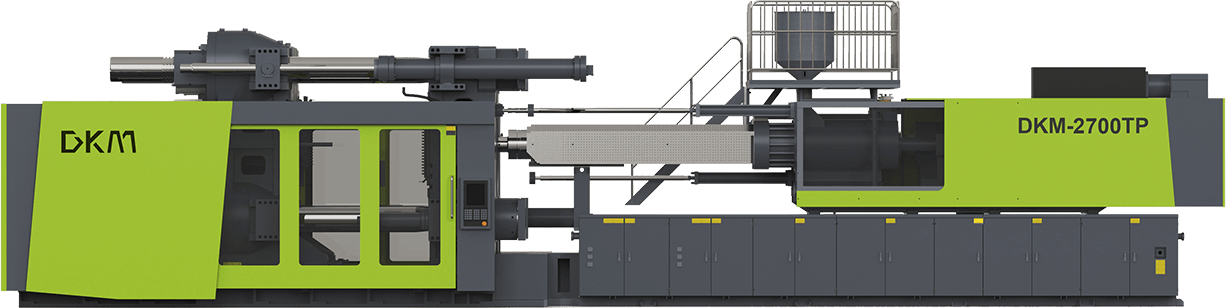

Plastic pallet injection molding machine

Plastic pallets are usually formed by one-time injection molding with large injection molding machines to ensure the products are strong and durable. DKM can provide two-plate injection molding machines (400-4000T) and large servo injection molding machines (1650-4000T). When choosing a machine, it is necessary to consider whether the sliding distance of the injection molding cylinder is sufficient and whether there are supporting equipment for plastic pallet injection molding, etc.

Auxiliary equipment

In addition to injection molding machines and molds, plastic pallet injection molding production lines also require related auxiliary equipment, such as automatic feeders, dryers, mixers, side/inlet mechanical arms, chillers, etc. We can suggest an economically reasonable supporting plan based on the specific budget of the client.

Service Commitment

Pre-sales Service Process

1.Demand research and proposal development. Conduct research to understand the company’s current status and future development strategy, clarify functional planning requirements for the factory, and develop targeted factory layout planning solutions.

2.Business negotiation and contract signing. Budget quotation + business negotiation confirmation; contract terms drafting + contract communication and signing.

3.Planning and project monitoring. Submit implementation results in stages: new plant planning functional division, large logistics flow design, production mode optimization, capacity design, warehouse configuration planning, etc. Conduct confirmation of planning results.

4.Implementation guidance and continuous follow-up. Provide guidance for the implementation of planning solutions and follow-up services.

01-Project Initiation

Project Scope

Project Organizational Structure

Project Technology

02-Requirements phase

Define user requirements

URS/RTM/RAM

Project plan

Validation plan

Deliverables list

03-Design phase

PS

DS(IDS/HDS/FDS)

Test plan and procedure

DQ

04-Implementation phase

Development environment

Test environment

Production environment

Implementation records

Issue tracking

Change and deviation handling

Internal testing

C&Q

05-Acceptance Phase

Operating Environment

System Import

User Training

Test Records

FAT(IQ)

SAT(OQ)

06-System Go-Live

Sign Off

System Handover

Document Delivery

Maintenance and Technical Support

Project Quality Assurance

Project Quality Control

Project Team Consultant Expertise Guarantee

After-sales Service Guarantee

Turnkey Project

24/7 After-sales Service

Additional Services